| Type R |

Inner and outer diameter reinforced with plies of metal without filler |

Greater stability and better compression characteristics. Tongue & groove /male &

female/groove to flat face flange

assemblies.

|

| Type RIR |

Solid inner metal ring as compression stop to fill annular space between flange bore &

inside diameter of gasket. |

Prevent accumulation of solids, reduce process fluids turbulent flow and minimize flange

face erosion. Suitable for male

and female pipe flanges.

|

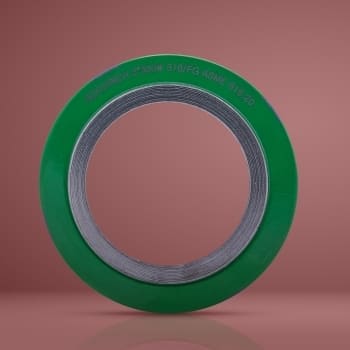

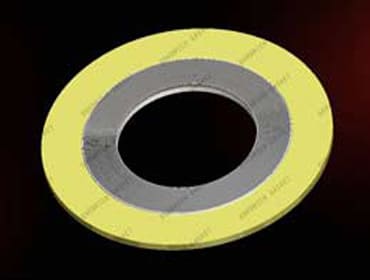

| Type CG |

External ring centering gasket on flange face for more radial strength. |

Prevent gasket blowout, compression stop. Suitable for Flat & raised face flanges.

|

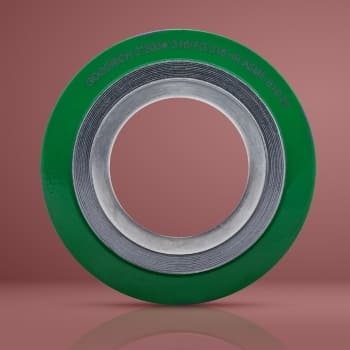

| Type CGI |

Solid metal Inner ring acc. to ASME B16.20 for class 900, 1500, 2500, NPS greater than

24”, 12”, 4” resp. & metal

winding of same material. |

Suction side of pumps /compressors, smooth surface finish (125 Ra max), prevent over

compression of gasket. Suitable for

Flat & raised face flanges, corrosive/ toxic media, high press. /high temp. Service.

|

| Type HE |

Standard spiral wound on outer portion & single or double jacketed for pass bar,

fastened to ID of spiral wound portion. |

As Heat exchanger gaskets with heat exchangers requiring pass bars.

|

| Type HE-CG |

Similar to Type HE with outer guide ring & spiral wound primary seal. |

Resiliency and excellent sealing quality.

|

| Type HE-CGI |

Varied CGI with an inner ring & spiral wound steel nose/ solid metal outer ring. |

Accurate gasket location. Used in Heat exchangers, TEMA type flange arrangements.

|

| Type CG-RJ |

Special sized CG gasket with outer ring to cover ring joint grooves. |

Maintenance repair item prevents SPW portion from entering groove & suitable for

Standard ring joint flanges.

|

| Type M, MC, MCS |

MC has Pre-formed inner &/or outer rings of spiral winding with a centering guide. MCS

has a solid metal inner &/or

outer ring. |

Boiler manholes cover assembly, high pressure systems. Depending on manhole plate

configuration these are oval, round,

obround in shape & prevent shouldering and pinching due to radial misplacement.

|

| Type T |

Round, oval, square, diamond, obround, pear shaped gaskets. |

Boiler hand hole & tube cap assemblies. Relies on internal pressure in boiler to seat

the gasket.

|

| Type 625 |

Similar to Type R & 0.0625” thick. |

High pressure sealing in space restricted applications.

|

| Carrier Ring |

Integral construction of 2 spiral wound gaskets placed in a specially machined metallic

ring. |

High recovery & Ease of handling.

|